In the ever-evolving world of electronics, choosing the right printed circuit board is critical to ensuring optimal performance and reliability. Among the various PCB configurations available, 4-layer heavy copper PCBs stand out for their unique benefits and applications. This blog post explores the advantages of using 4-layer heavy copper PCBs, providing users and consumers with insights into why this type of PCB may be an ideal choice for their specific needs.

Enhanced Current Carrying Capacity with 4-layer Heavy Copper PCBs

One of the most notable advantages of 4-layer heavy copper PCBs is their enhanced current carrying capacity. Heavy copper PCBs have thicker copper layers than standard PCBs, enabling them to handle higher currents without generating excessive heat. This is particularly beneficial in applications that require high power, such as in power supplies, motor controllers, and high-current circuits.

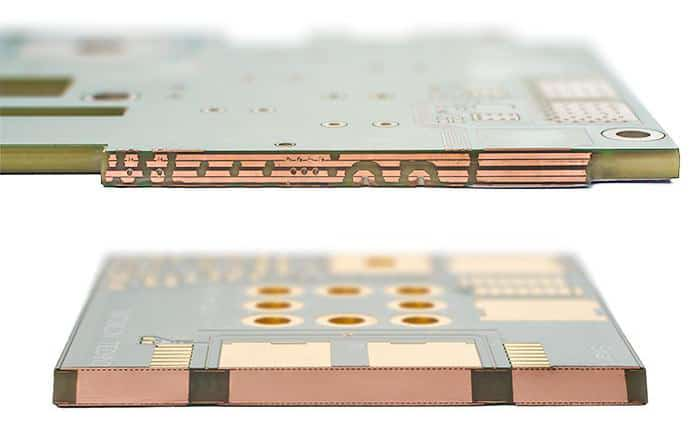

4-layer heavy copper PCBs typically have a copper thickness of 3 oz/ft2 to 10 oz/ft2, compared to the standard thickness of 1 oz/ft2. The increased thickness provides excellent thermal conductivity and reduces the resistance of the copper traces, which improves the PCB’s ability to handle high currents. For designers and engineers, this means they can develop more robust and reliable high-power electronic systems without having to worry about overheating or excessive voltage drops.

Improved Thermal Management with 4-layer Heavy Copper PCBs

Effective thermal management is critical for high-power electronic applications to prevent overheating and ensure the life of components. 4-layer heavy copper PCBs excel in this regard because of their excellent thermal conductivity. The increased copper thickness dissipates heat more effectively, helping to maintain the optimal operating temperature of sensitive components.

In a 4-layer heavy copper PCB, the heat generated by high-power components can be effectively transferred from the source and spread across the PCB. This helps prevent localized hot spots that can cause component failure or performance degradation. For applications such as power converters and automotive electronics where thermal management is critical, thick copper layers provide significant advantages by enhancing the overall thermal performance of the PCB.

Enhanced Durability and Reliability of 4-layer Heavy Copper PCBs

Durability and reliability are essential factors in the performance of electronic systems, especially in harsh environments. 4-layer thick copper PCBs offer enhanced mechanical strength and durability compared to standard PCBs. Thicker copper layers contribute to a stronger, more resilient board that can withstand mechanical stress and environmental conditions.

Thick copper PCBs are less prone to issues such as line damage, delamination, and mechanical failure. This enhanced durability makes them suitable for applications in harsh environments, including automotive, aerospace, and industrial machinery. For users and manufacturers seeking reliable and long-lasting solutions, 4-layer thick copper PCBs provide the necessary robustness to ensure continued performance and reliability in challenging conditions.

It can improve electrical performance

Electrical performance is an essential consideration in PCB design, and copper layer thickness can significantly affect this performance. Quad-layer thick copper PCBs offer better electrical performance due to their lower resistance and better conductivity. This reduces signal loss, lowers impedance, and minimizes voltage drop, all of which contribute to better overall performance.

In high-speed digital and RF applications, it is critical to maintain signal integrity. The increased copper thickness in quad-layer thick copper PCBs helps achieve better impedance control and reduce signal interference, ensuring that high-frequency signals are accurately transmitted. For designers working on high-performance electronic products, the improved electrical characteristics of thick copper PCBs can lead to more efficient and reliable circuit designs.

Cost efficiency and long-term advantages

While the initial cost of quad-layer thick copper PCBs may be higher than standard PCBs, they offer long-term cost efficiency due to their enhanced performance and durability. Improved current-carrying capacity, thermal management, and mechanical strength reduce the likelihood of failure and the need for frequent replacement or repair. This can save a lot of money over the life of the product.

For manufacturers and users, investing in 4-layer heavy copper PCBs can reduce maintenance costs, reduce product recalls, and improve customer satisfaction. The long-term benefits of improved reliability and performance often outweigh the initial cost, making heavy copper PCBs an affordable choice for high-power and demanding applications.

Versatility and Range of Applications

The versatility of 4-layer heavy copper PCBs makes them suitable for a wide range of applications across industries. Its ability to handle high currents, manage heat, and provide mechanical solid support means it can be used in a variety of fields, including automotive electronics, power supplies, telecommunications, and industrial control.

Whether it is used for power management in electric vehicles, signal processing in communication systems, or control systems in industrial automation, 4-layer thick copper PCBs provide the performance and reliability needed to meet specific application requirements. This versatility ensures that users can rely on thick copper PCBs for a wide range of electronic designs and applications.

The Value of Choosing 4-layer Heavy Copper PCBs

In summary, 4-layer Heavy Copper PCBs offer numerous advantages that make them a valuable choice for high-power and demanding electronic applications. Their enhanced current-carrying capabilities, improved thermal management, and increased durability provide significant benefits in terms of performance and reliability. In addition, improved electrical characteristics and long-term cost-effectiveness further enhance their value as an excellent solution for complex electronic designs.